11-05-2024, 05:09 PM

|

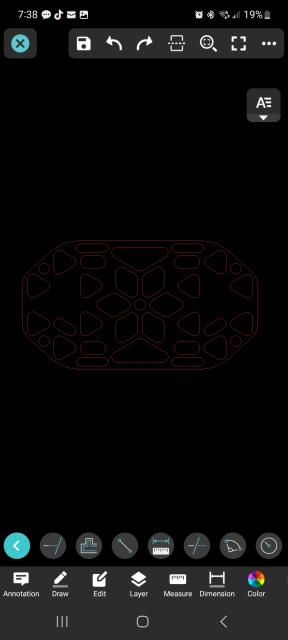

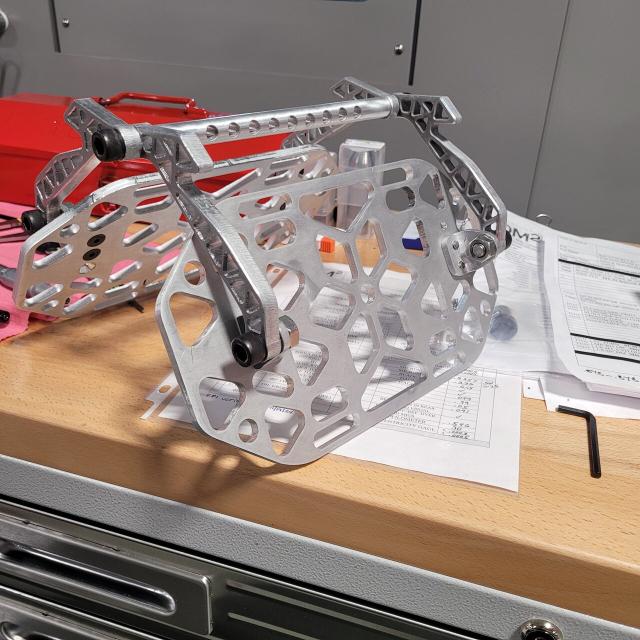

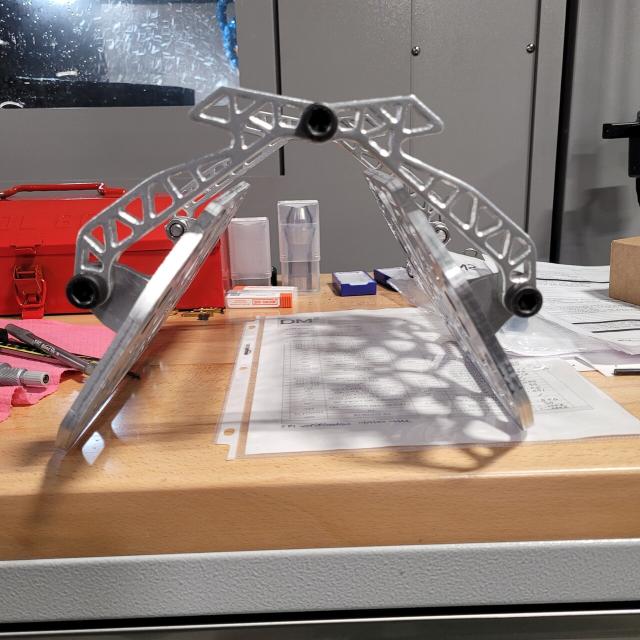

Saddle prototype

|

|

11-20-2024, 05:46 PM

12-02-2024, 11:01 AM

12-03-2024, 07:17 AM

Very nice! I love seeing this come together. Thanks so much for sharing your progress!

12-03-2024, 08:34 AM

(12-03-2024, 07:17 AM)Nanno Wrote: Very nice! I love seeing this come together. Thanks so much for sharing your progress! Thanks! My new side boards came in Saturday I should have them finished by Thursday. This new design will have extra evenly spaced holes for the cross buck mounts so it can be moved farther up the board if needed. and instead of doing like my first one and using Marc's pouch design I added slots for buckles to slide through to hold the pads to the saddle so then the boards will be visible. And overall it'll weigh 2ish pounds less than Marc's saddles.

12-03-2024, 10:49 PM

It is looking really good!

12-04-2024, 12:19 AM

12-18-2024, 02:20 PM

(12-04-2024, 12:19 AM)Moorefieldc Wrote: Forgot my tap at the house for the rigging locations but the boards are mounted with an his extra hole for more adjustability.I haven’t been on this website for awhile. I wish I would have noticed your saddle build sooner. The biggest complaint I had about Marc’s saddles is that there are too many parts that could come loose. I get it, custom fitted saddles. I have packed with people who have his saddles. They always seem to be torquing down the center bolt. Guess what? A saddle become loose and he lost the wrench to tighten the saddles in our backcountry camp. He could not find it and the repercussions of this was him having to redistribute his gear that the goat could no longer carry onto his other goat’s. I researched so many designs of saddles over the years. Butthead Packgoats offer custom made wood saddles. They are so much more affordable and the company even sent me a Christmas card thanking me. I believe custom building a saddle is the best option. Extremely easy to properly fit your goats. I do have a suggestion for your build. If you are dead set on keeping the center bolt. I am not sure need that because of the massive sideboards are more than strong enough to provide rigidity to the saddle, you wanted a lighter saddle than Marc right? Send that exact design to people with the center bolt. Have them fit the saddle to their fully grown goat(important) then have them send it back. Weld the custom angles that the center bolt provided then you remove the center bolt. Solve the needed hardware just to loose it when you need it most. Remove the center pin and ditch the hardware. Create a lighter saddle that cannot come loose. How much does a center bolt and its sleeve weigh? How much does not having to carry hardware that you are likely to loose weigh? Another 1/4-1/2 pound? Also take into consideration all of the straps and rigging that needs to be fitted. That’s a lot of material to trap heat and exhaust your goats sooner. If you want a saddle that is superior to Marc’s I think my suggestions are worth taking in to consideration.

12-18-2024, 02:26 PM

It is a beautiful saddle by the way. It’s a shame to cover up those side boards. Is the padding actually needed for the side boards? Is there another way of thinking about it. The design pattern you cut out of the sideboards could create extremely beneficial ways for heat to escape. Breathe ability.

12-18-2024, 02:38 PM

Or build a jig you send out and have people form for fit their goats. They send it back to you and you build a saddle based on those dimensions. Butthead Packgoats sent me a description on how to find the proper angle of the front and rear cross buck. It was years ago but it was using paper cutouts of triangles to fit the goat. I sent the cardboard cutouts back to them and they built their custom fitted saddle.

|

|

« Next Oldest | Next Newest »

|

Users browsing this thread: 2 Guest(s)